Navigating Water Delivery Business Obstacles; Speedy’s Potable Water

An Information Article on Being a Water Delivery Driver

From the arid landscapes of the Mojave Desert to the agriculturally productive landscapes of Central Valley, running a water delivery business in California is a complex profession. Among the pioneers in overcoming the challenges posed by the water management obstacles in California is Speedy’s Potable Water. This case study delves into how Speedy’s has utilized cutting-edge technology and strategic planning to navigate water delivery management.

Speedy’s Approach

Reliability even in the face of their customer’s changing water needs

Speedy’s Potable Water has distinguished itself not only for the quality of its services but also for its exceptional efficiency and professionalism. With a commitment to exceeding customer expectations, Speedy’s employs a multifaceted approach to water delivery. They ensure reliability even in the face of their customer’s changing water needs.

The Power of PTLevel Delivery Management Portal:

One of the key factors allowing Speedy’s to stay ahead of their competitors is the implementation of the PTLevel Delivery Management Portal. This advanced application allows water delivery businesses to meticulously plan deliveries which prevents wasteful trips and ensures a focused effort on averting water outages for their customers. By leveraging data analytics and real-time monitoring, Speedy’s can optimize routes, plan staffing effectively, and respond promptly to changing demands. Sorting columns by “Current Level” or “Address” (etc) makes delivery planning a breeze, especially for splitting deliveries between 2 or more customers.

PTDevices Delivery Management Portal

Water Delivery Management and Efficiency:

Recognizing that the key to overcoming water outages and staying competitive in a demanding business lies in efficiency, Speedy’s Potable Water has made significant investments. With a focus on the right water delivery trucks and a team of reliable delivery drivers, their investments are making a positive financial impact This strategic move minimizes downtime, enhances overall service quality, and builds trust with both customers and stakeholders.

Water Delivery Management and Fuel Savings:

One of the noteworthy outcomes of Speedy’s adoption of using PTLevel’s and the portal is the substantial savings in gas money. Over the past two years, Speedy’s estimates that they have saved over 15-18% of their regular fuel budget! Simply by streamlining their delivery routes and optimizing their operations these fuel savings were easily achieved. This not only contributes to the company’s bottom line but also aligns with broader environmental goals by reducing the carbon footprint associated with delivery operations.

Comprehensive Services Offered by Speedy’s:

Speedy’s Potable Water goes beyond traditional water delivery services. The company’s diverse offerings include:

– Potable water delivery

– Emergency same-day service

– Holding tank filling and maintenance

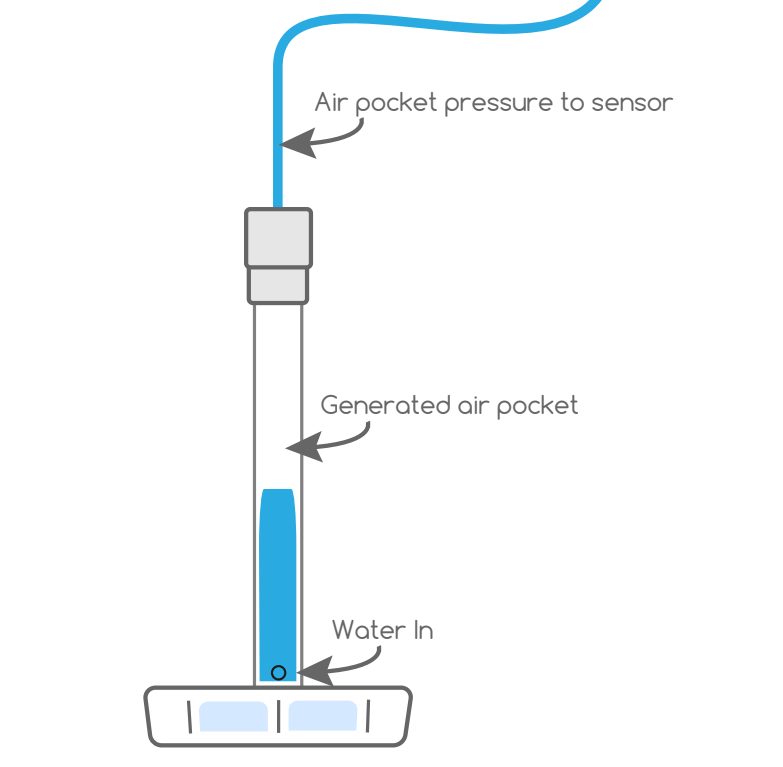

– Tank monitoring systems

– Tank cleaning and refilling services

– Pool and pond filling and top-offs

These comprehensive services ensure that Speedy’s remains a versatile and reliable partner for various water-related needs in California.

Check out Speedy’s Website for additional details

Additional Information on the PTLevel Delivery Management Portal Features:

Client Notes:

With the Device Management account, water delivery companies have the ability to add private notes to each client account they have permission to work with. Their client’s won’t be able to see the notes but the water company can use them to organize and keep track of information related to each client.

Device Management Alerts:

With the free Device Management Account, water delivery businesses have the ability to setup their own Device Manager Alerts with their client’s devices. The client and the water delivery company can each have their own alerts on the same device! With the free account, there are 2 free alerts points per device; for example an SMS alert at 20% and an email alert at 90%. These alerts points send notifications when the level goes above and below the threshold. (Read about the Premium Account here for information on unlimited alerts).

Client List and Client Maps:

With the free Device Management Account, there are also Client List and Map Views of all the clients and their devices that have given permission to their “manager” to manage. Order the list by client name, address, phone number, status, etc! Or, log into the device manager account and view a map centered on the main area of the clients managed. The pins that show are the client locations based on what is entered into their account profiles. Select the pin to see the related devices. The pin colors also represent the status of the devices in those client accounts (full, low, and empty statuses).

Client Maps in the PTDevices Management Portal

Other Features for Water Delivery Businesses:

Explore other PTLevel Device Management Features such as White Labelling, creating customer accounts, and then calibrating customer devices. Also view permission levels (viewing access, editing access, adding devices access), becoming a wholesaler, and more! Re-selling and installing PTLevel’s are a great way to add another revenue stream for water delivery businesses.

Conclusion:

Despite California’s challenging water management needs, Speedy’s Potable Water emerges as a beacon of innovation and efficiency. By leveraging the power of PTLevel, the Delivery Management Portal, investing in the right resources, and emphasizing environmental responsibility, Speedy’s not only ensures its own sustainability but also plays a crucial role in alleviating the impact of water scarcity on its customers.